薄膜电极、电解质和钝化层

通过在纳米结构化 3D 锂离子电池中实施基于锂的原子层沉积 (ALD) 膜,最近有报告显示功率密度、充放电期间的循环性能和安全性显著增加。

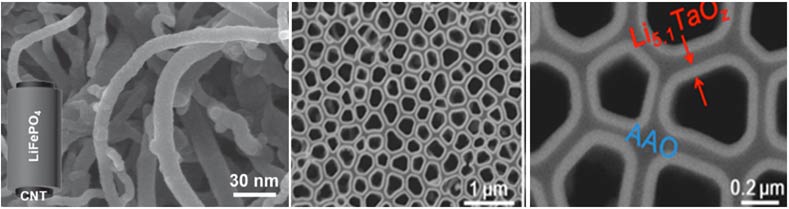

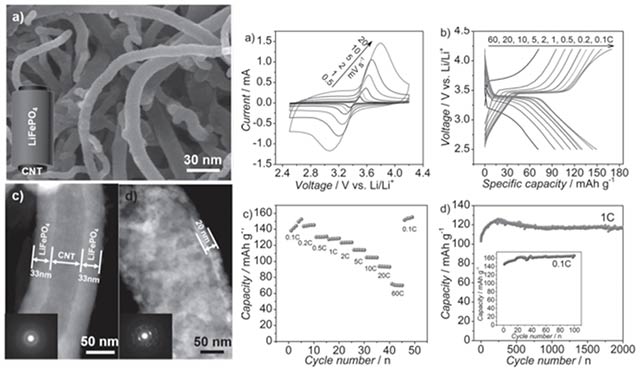

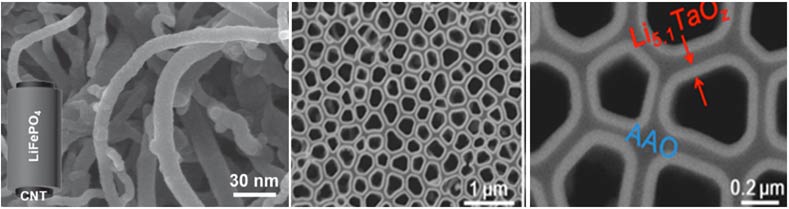

使用 Veeco CNT 原子层沉积 (ALD) 平台,具有高特定容量的电化学活性材料(例如 LiCoO2、LiMn2O4 三元或锂过渡金属磷酸盐四元链(例如 LiFePO4)已成功沉积在高纵横比 3D 纳米结构上,导致快速离子传输和功率密度增加。

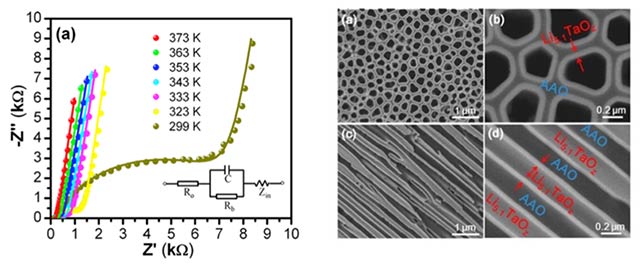

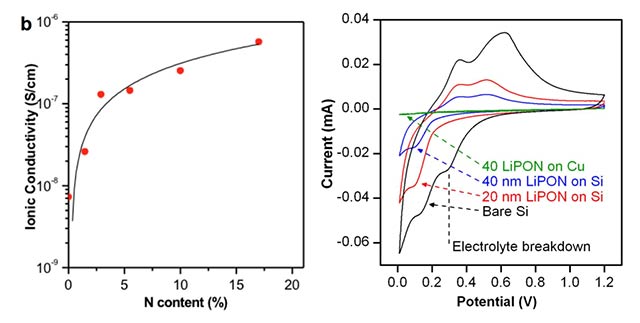

固态电解质(例如磷酸锂[8]、钽锂 [12] 或 LiPON [2])已沉积在 Savannah® 和 Fiji® 平台上以实现可调谐的高离子导电性。

另外经证实,在电化学循环期间,通过抑制过渡金属的溶解,同时使锂离子通过钝化层扩散,非常薄的钝化层(例如 Al2O3,<1nm)可显著改善 LIB 的容量保持。[15] 最近,Xiao 和 al. 已经使用具有电化学活性的 FePO4 涂层优化了 LiNi0.5Mn1.5O4 阴极材料的性能层[6]。

3D 锂离子电池的原子层沉积 (ALD) 优势

- 更高功率

- 3D 纳米结构的较短扩散路径导致功率密度更高

- 放电速率

- 因高表面积比率而改善的充放电速率

- 周期寿命

- 使用原子层沉积 (ALD) 钝化层和低应力薄膜改善的周期寿命

- 安全

- 非易燃固态电解质

沉积在碳纳米管上的保形 LiFePO4 阴极膜表现出出色的放电容量和速率能力 [10]

Li5.1TaO2 固体电解质沉积在高纵横比 AAO 中,锂离子传导性为 2E-8S/cm [13]

原位 XPS 示范无碳 Li2O 原子层沉积 (ALD)(Fiji® 中的 LiOtBu / H2O)

通过原子层沉积 (ALD) 沉积的 LiPON 固体电解质。离子导电率在膜中调节了 %N 含量 [2]

参考 – 最近在 Veeco CNT 原子层沉积 (ALD)平台上完成的出版物

- Liu, J. et al. Atomically Precise Growth of Sodium Titanates as Anode Materials for High-Rate and Ultralong Cycle-Life Sodium-Ion Batteries. J. Mater. Chem. A (2015). doi:10.1039/C5TA08435K

- Kozen, A. C., Pearse, A. J., Lin, C.-F., Noked, M. & Rubloff, G. W. Atomic Layer Deposition of the Solid Electrolyte LiPON. Chem Mater 150709110756002–13 (2015). doi:10.1021/acs.chemmater.5b01654

- Ahmed, B. et al. Surface Passivation of MoO3 Nanorods by Atomic Layer Deposition toward High Rate Durable Li Ion Battery Anodes. Acs Appl Mater Inter 150612140338000–10 (2015). doi:10.1021/acsami.5b03395

- Ahmed, B., Anjum, D. H., Hedhili, M. N. & Alshareef, H. N. Mechanistic Insight into the Stability of HfO2‐Coated MoS2 Nanosheet Anodes for Sodium Ion Batteries. Small n/a–n/a (2015). doi:10.1002/smll.201500919

- Kozen, A. C. et al. Next-Generation Lithium Metal Anode Engineering via Atomic Layer Deposition. ACS Nano 150513155622005–30 (2015). doi:10.1021/acsnano.5b02166

- Xiao, B. et al. Unravelling the Role of Electrochemically Active FePO4 Coating by Atomic Layer Deposition for Increased High‐Voltage Stability of LiNi0.5Mn1.5O4 Cathode Material. Advanced Science n/a–n/a (2015). doi:10.1002/advs.201500022

- Liu, J. et al. Atomic layer deposition of amorphous iron phosphates on carbon nanotubes as cathode materials for lithium-ion batteries. Electrochimica Acta (2014). doi:10.1016/j.electacta.2014.12.158

- Wang, B. et al. Atomic layer deposition of lithium phosphates as solid-state electrolytes for all-solid-state microbatteries. Nanotechnology 25, 504007 (2014).

- Kozen, A. C. et al. Atomic Layer Deposition and In-situ Characterization of Ultraclean Lithium Oxide and Lithium Hydroxide. J. Phys. Chem. C 141106012144006 (2014). doi:10.1021/jp509298r

- Liu, J. et al. Rational Design of Atomic-Layer-Deposited LiFePO4 as a High-Performance Cathode for Lithium-Ion Batteries. Advanced Materials n/a–n/a (2014). doi:10.1002/adma.201401805

- Yesibolati, N. et al. SnO2 Anode Surface Passivation by Atomic Layer Deposited HfO2 Improves Li-Ion Battery Performance. Small n/a–n/a (2014). doi:10.1002/smll.201303898

- Lecordier, L., Insitu process optimization of lithium-based multicomponent oxides, ALD2014, Kyoto Japan

- Liu, J. et al. Atomic Layer Deposition of Lithium Tantalate Solid-State Electrolytes. J. Phys. Chem. C 117, 20260–20267 (2013).

- Kim, H. et al. Plasma‐Enhanced Atomic Layer Deposition of Ultrathin Oxide Coatings for Stabilized Lithium–Sulfur Batteries. Adv. Energy Mater. 3, 1308–1315 (2013).

- Bettge, M. et al. Improving high-capacity Li1.2Ni0.15Mn0.55Co0.1O2-based lithium-ion cells by modifiying the positive electrode with alumina. J Power Sources 233, 346–357 (2013).

- Lee, J.-T., Wang, F.-M., Cheng, C.-S., Li, C.-C. & Lin, C.-H. Low-temperature atomic layer deposited Al2O3 thin film on layer structure cathode for enhanced cycleability in lithium-ion batteries. Electrochimica Acta 5,5 4002–4006 (2010).